In Station Diagnostics: Vapor Recovery Monitoring Systems

• Pressure Integrity Test Weekly system leak detection: Warning alarm for rates at least 2 times the rate allowed in CP 201, Static Pressure Performance 4.2. With two consecutive failed assessments, a failure alarm is activated, recorded, and fuel dispensing is shut down from the affected fueling point(s).

Fuel Storage Tanks Above Ground Double Wall Steel

Above Ground Fuel Storage Tanks: Perfect For Any Application. Diesel Fuel Storage: Envirosafe’s Fireguard and Flameshield tanks are perfect for bulk diesel storage. Our double wall steel diesel fuel storage tanks come in sizes from 1,000 gallon to 20,000 gallon and are perfect for the trucking industry and municipal fuel needs.

UST System Inspection Checklist NWGLDE

Leak Detection Sensor Correct position and height. X No abnormal appearance of piping or components. (Rust, discoloration, delamination, swelling, X Test boot (if applicable) pulled back so interstice is not blocked or obstructed. X Product Shear Valve Properly secured and anchored. Installed at the proper level. No leaks. X Properly secured and anchored. X

Guidance Manual on Underground Fuel Storage Tank

Guidance Manual on Underground Fuel Storage Tank Installations Research & Contractor: Fluor Daniel GTI International Ltd monitoring/testing systems). For tank, the different types are introduced A sub section covers leak detection, monitoring and testing systems (e.g. interstitial monitoring of double skinned tanks Jnd

Ancillary Station Items Decals: Identification Fuel

Source North America Corporation provides a large assortment of service station accessories that fuel retailers need to maintain a busy, customer friendly gas station. Fuel site operators know that top quality, service station accessories are just as important for maintaining customer loyalty as dependable dispenser equipment.

Gas station underground fuel tanks Manufacturers

gas station underground fuel tanks manufacturer/supplier, China gas station underground fuel tanks manufacturer & factory list, find qualified Chinese gas station underground fuel tanks manufacturers, suppliers, factories, exporters & wholesalers quickly on .

Florida UST Training Class A B & C Operator State

Florida Administrative Code (FAC) Chapter 62 761, Underground Storage Tank (UST) Systems defines and outlines the responsibilities of UST systems and operators. All Class A, B and C UST operators should have been trained by Aug . Operator Training and Certification.

Franklin Fueling Systems Americas

Total System Solutions™ We offer the world's most complete line of petroleum equipment including Submersible Pumping Systems, Piping & Containment Systems, Service Station Hardware, Dispensing Systems, Fuel Management Systems and Transport Systems.

Oil & Fuel Leak Detection Systems CMR Electrical

Fuel & Oil leak detection systems are designed to detect the presence of leaking fuel oil, kerosene and diesel. Uses include detection of leaking storage tanks, leaks from fuel pumps, leaks within bunded fuel tanks, Pipe in pipe leak, generators leaking fuel onto the floor and many other applications.

Indiana UST Training Class A B & C Operator State

The exam assures that underground storage tank system operators possess the necessary knowledge regarding the proper operation of underground storage tank systems. A test is not required for the Class C operator, but those persons must be properly trained.

Underground Storage Tank (UST) Monitoring Systems

Many systems are capable of monitoring double wall tanks and lines, pressurized piping and providing remote communication. UST monitoring systems are also referred to as fuel management systems, automatic tank gauge and leak detection systems.

Underground Fuel Storage Tanks Oil Diesel

The photos above are of a leaking and costly underground storage tank removal, caused the gas station to be shut down. EPA was involved and it is still inoperable at present. Underground fuel and oil tanks rust, corrode, and can begin leaking, contaminating the environment most notably water and soil. Water and Soil Contamination.

Petrol Fuel Diesel Station Underground Double Wall Pipe

Petrol Fuel Diesel Station Underground Double Wall Pipe Leak Alarm Ayatem Leakage Detector(id:9945699), View quality leak detector, leakage detection, leak alarm details from Qingdao Guihe Measurement&Control Technology Co.,Ltd storefront on . Buy best Petrol Fuel Diesel Station Underground Double Wall Pipe Leak Alarm Ayatem Leakage Detector with escrow buyer

China Underground Oil Storage Tank with UL Certification

China Underground Oil Storage Tank with UL Certification, Find details about China Stoarge Tank, Storage Fuel Tank from Underground Oil Storage Tank with UL Certification Luqiang Energy Equipment Co., Ltd.

Auto leak alarm detector sensor with controller for

gas station ATG/ automatic tank gauge, hose type tanker truck ATG , Magnetostrictive probe , touch contorl sonsole , management system . double wall pipe leakage detector , double wall tank leakage detector , Tank Calibration system/machine, high level alarm , gas alarm ,and others.

STP MLD

The STP MLD units test the delivery pipeline system up to the solenoid valve in the dispenser for leaks whenever the static system pressure has fallen to one PSI or less, and within 3 to 4 seconds (depending on model) allows full flow if the system has no leaks. A leak smaller than the required 3 GPH detection level, any air or vapor trapped in the system, or systems with pressure below 26 PSI, will lengthen the

Wetstock Reconciliation at Fuel Storage Facilities

refurbished petrol stations, automatic detection systems can be incorporated into the installation of the underground tank and pipeline in order to monitor for leaks and raise an alarm. However, for older petrol stations this is not always feasible and some other method must be adopted to

June 2000 Understanding Line Leak Detection Systems

June 2000 Understanding Line Leak Detection Systems 2.1 INTRODUCTION TO MECHANICAL LINE LEAK DETECTORS Mechanical Line Leak Detectors (MLLDs) are pressure operated valves designed to de tect leaks of 3 or more gallons per hour (gph). Typically, they are installed on the head of the submersible pump located in a sump (see Figure 5).

Daily inventory & Page 1 StatiStical inventory analySiS D

Inventory control is probably the oldest form of fuel storage leak detection. It is also an essential UST system management practice. Inventory records reflect everything that happens to the fuel in your storage system between the fill cap and the dispenser meter,

US Patent Application for Method And Apparatus For

A method of determining the thermal status of fuel in a fuel distribution system (10) includes pressurizing the distribution line (16) by activating a submersible pump (14) in an underground storage tank (12). Once the distribution line (16) is pressurized, the pump (14) is switched off, and the reverse flow rate out of the distribution line back into the tank (12) is monitored.

Virginia DEQ Underground Storage Tanks

Underground Storage Tanks Program overview. The Virginia Department of Environmental Quality implements the UST program under Article 9 of State Water Control Law. Article 9, first enacted in 1987, enables DEQ to receive UST notifications, receive federal grant funds, develop regulations, conduct cleanups, and provide overall supervision of UST activities in the state.

Energy Solutions SPATCO

Whether you’re dispensing unleaded fuel, diesel, natural gas, or diesel exhaust fluid, SPATCO provides energy solutions that meet your needs.

Tank Gauging System Emerson US

Tank gauging means liquid measurement in large storage tanks to determine product volume. Rosemount™ Tank Gauging System ensures accurate level, temperature, and pressure measurements for inventory control, oil movement and overfill prevention, securing efficient operations.

Omntec Tank Monitoring and Leak Detection Systems

OMNTEC® Mfg., Inc., is an Internationally recognized manufacturer of leak detection systems and gauging products for the petroleum industry. Omntec Tank Monitoring and Leak Detection Systems Call Us: +1 (877) 814 2001

Underground Oil Tank Inspection ATS Environemental

No. ATS uses state of the art technology that will not harm the underground tank. Years ago, many companies used air pressure testing as a means to evaluate underground tank systems. This type of testing could potentially damage the tank and associated piping. Today, strict pressure testing is not an approved test method in most states.

Automatic Tank Gauge Systems Tank Gauge Magentostrictive

The tank gauge console is the tank monitor, one key part of the complete automatic tank gauging system. With the tank monitor, you can watch the detail information of underground storage tanks or aboveground storage tanks, like fuel density, product level, water level, temperature, etc.

Fire Protection Systems 108 Flashcards Quizlet

Self contained pre engineered or engineered systems that use a number of different components, including fixed nozzles, piping, control panels, automatic detection, manual activation devices, releasing mechanisms, alarm devices, control valves, and cylinders to hold the agent; these systems protect computer rooms, electronic equipment, flammable and combustible liquids and gases, aircraft

Methods of Leak Detection for Underground Storage Tanks

All regulated tanks must have leak detection (often also called release detection) so that leaks are discovered quickly before contamination spreads from the Underground Storage Tank (UST) site. You must provide your UST system with release detection

Preventing Groundwater Contamination at Gas Stations—

The guiding principle of stormwater management at gas stations is to keep clean water clean. Relatively clean stormwater, such as from roofs and areas other than the fueling area, may not be allowed to run onto the fuel dispensing area (Env Wm (al)).

Introduction to Leak Detection: Understanding Federal

Types of piping systems Suction piping systems use a vacuum to draw the pro duct from the tank to the dispenser. Pressurized piping systems use a pump at the bottom of the tank to push the product to the dispenser. 2. Leak detection requirements for piping differ based on the type of piping system used.

Cantest Solutions Inc. Corporate Site

SIR is a method for monitoring leaks within underground storage tanks (UST). Data is gathered and reported on a computer software for statistical analysis. With Federal and Provincial Laws requiring a method of leak detection on all USTs, SIR provides an inexpensive and effective solution.

Tank IQ: Training Guide for Class A and B UST Operators

Note: Definitions for CBS facilities and tank systems may differ. Refer to 6 NYCRR Part 596.1(c). Term Definition 0F0F0F0F Automatic tank gauge (ATG) Probe inside a tank that measures product and water level and can conduct in tank testing. An ATG is usually part of an electronic monitoring system. Category 1

Gas station management system ATG/Leakage detection/Valve

Gas station management system ATG/Leakage detection/Valve controller/Fuel Dispenser leak alram controller sensor Product Introduction Double deck Tank Leakage Detecting Instrument consist of GH SLI Console and SYW E Sensor. It can make a distinction between water and oil, enjoys real time monitoring function.

NC DEQ: Underground Storage Tank Section

The Underground Storage Tank Section consists of three branches.. The Permits and Inspection Branch issues permits to operate UST systems and inspects UST facilities to ensure compliance with UST statutes, rules and policies. In addition to helping develop and review statutes, the staff provides technical assistance to enhance compliance and prevent pollution.

Petrol Station Equipment Underground Diesel Fuel Tank

Touch control console installed in the petrol station control room, it can automatically probe data acquisition and processing, real time display tank storage information, realize the tank leak detection, automatic unloading, record query, control multi channel submersible pump,oil level alarm, data upload, and other functions.

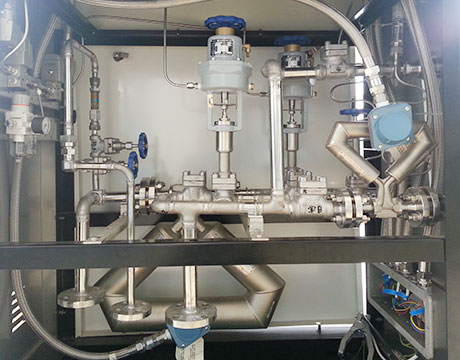

Aboveground Fuel Storage and Dispensing System

As part of this project, CommTank provided two complete working storage tanks, new fuel dispensing systems, leak detection and monitoring equipment, and fuel management system.

Failure modes and effects analysis (FMEA) for the security

In order to effectively analyze the security of the supply chain system of the gas station, this study set the gas station as the center, then the upstream suppliers and downstream consumers were classified into three sub systems, and the whole system was analyzed by using the method of failure modes and effects analysis (FMEA).

UIDANCE FOR NDERGROUND TORAGE ANK ANAGEMENT AT

An automatic tank gauging (ATG) system with water monitoring capability is an ideal method, as long as the sensors are maintained to be functional. Some guidelines suggest comparing the product level reading taken with a manual tank gauge with that on the ATG because discrepancies may indicate water.

Contact Us OPW Retail Fueling

Underground storage equipment is designed to help protect the environment by providing fuel operations with hazard prevention equipment. View Products Standard Dispensing Equipment View Products

Fire & Explosion Risks in Service Stations

The level of risk associated with fuel leakage means early detection of leaks is essential. Immediate corrective action must be taken when leaks are detected. Therefore there is need for consistent and accurate monitoring of fuel delivered, stored and dispensed at any service station in order to detect leaks from each underground tank and

New Jersey Fuel Dispensing Facilities Compliance Calendar

Upon failure of the test the Permitee shall repair and retest any vapor control system within 14 days of failure. Upon failure of the retest the Permitee shall notify the Department in writing within 72 hours of the failure to NJDEP. *** Refer to your air permit for requirements.

Tank Level Sensor Products & Suppliers Engineering360

Description: Versatile LS04 Series Liquid Level Sensor for single, multi and continuous level control, detection and monitoring. Reservoir, tank, bottle or other container mounting configurations. Up to 6 floats, 1W 100W rated power, other cables, connectors.

Fuel Management Systems Franklin Fueling Systems Americas

A complete line of cutting edge tank gauge consoles and state of the art leak detection make our Fuel Management Systems product line the industry’s premier brand for total system control. Compliance, inventory management, and leak detection monitoring are made easy for every user with the industry’s most intuitive tank gauge user interface.

Service Station Equipment Fuel Transfer Pumps Gas

Service Station Equipment and Gas Station Supplies from Centerflo, Cim Tek, CNI, DCI, Dixon, EBW, Emco Wheaton, EnviroLite, Ergodyne, ESCO, Global Light,Goodyear, GPI

Message

Message tel

tel Inquiry

Inquiry