Cargo Measurement Devices for Oil Tankers Liquid Level

The most important task on a tanker is the measurement of the cargo level. Inaccurate readings lead to pollution and environmental hazards. There are different instruments used for the measurement of cargo level. In this article we discuss the different level gauges used for the measurement of the cargo level which includes float gauges, UTI indicators, radar gauges, ultrasonic gauges, and

Marine Tank Gauging Solutions for All Ships

Marine Tank Gauging Solutions for All Ships. PSM’s marine tank gauging systems and instruments are accurate, robust and reliable enabling your vessels to operate efficiently and comply with safety and environmental regulations.

Cargo Tank Motor Vehicles

Pressure gauge opening restricted to .060" diameter (h)(4) Thermometer well/ thermometer required if using adjustable liquid level gauge (e) One or more fixed liquid level gauge required (h) Cargo Tank Motor Vehicles (continued)

AMETEK USG Pressure gauges, transmitters, diaphragm

AMETEK Sensors, Test & Calibration is one of the world's leading suppliers of pressure gauges, diaphragm seals, temperature gauges, pressure transducers, and pressure transmitters under the brands US Gauge, PMT Products, and Mansfield & Green.

Air Pressure Gauges for sale Censtar

Air Pressure Gauges. Air pressure gauges give you the ability to read and record air pressure data from a variety of devices. These measurement devices can be used in personal or professional applications. Some air pressure gauges might suit your needs better than others. What are some applications for air pressure gauges?

Marine Cargo Monitoring Marine Tank Management

Marine Cargo Monitoring Rosemount Cargo Monitoring System (CMS) Depending on tanker type, tanker size and cargo, Rosemount CMS is designed to be flexible and scalable for the demand and requirements of all types of tankers and cargoes with no compromise on reliability.

49 CFR § Requirements for test and inspection of

Each cargo tank of a multi cargo tank motor vehicle must be tested with adjacent cargo tanks empty and at atmospheric pressure. Test pressure must be maintained for at least 5 minutes. Cargo tanks in liquefied compressed gas service must be externally inspected for leaks during the leakage test .

Common Tank Gauging Technologies and How They Work Varec

Radar tank gauges are “downward looking” measuring system installed on the tank roof. Operating on the time of flight method, they measure the distance from the reference point (process connection) to the product surface. Radar impulses (FMCW principle) are emitted by an antenna, reflected off the product surface and received again by the

Tanker operation : Inspection Of Cargo Work Equipment And

Tanker operation : Inspection Of Cargo Work Equipment And Machinery refer to ‘Cargo Tank Level Gauge Alarm setting and Portable Gauge Record’ as listed in “Quarterly Testing Record of Miscellaneous Equipment” Routine monitoring of the accuracy of the fixed gauges are carried out using “Cargo Tank Level Gauge Check Record at

Cargo discharging operation in oil tankers ships business

For further confirmation of effective stripping with remote suction pressure gauge, closed system of manual sounding (dipping) of cargo tanks shall be done by the ship’s crew to ascertain the sludge / oil condition of tank bottom. Survey upon completion of discharge from tanks (Dry certificate /

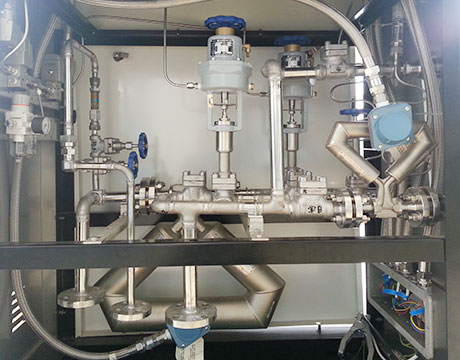

Tank Gauging System Emerson US

Tank gauging means liquid measurement in large storage tanks to determine product volume. Rosemount™ Tank Gauging System ensures accurate level, temperature, and pressure measurements for inventory control, oil movement and overfill prevention, securing efficient operations.

COPS (Cargo Oil Pumps) Used On Oil Tankers E Marine

Due to this fact officer in charge should keep an eye on the separator level gauges, pump suction/discharge gauges and pump temperatures and log them hourly. As the liquid level in tank gets low pump will experience some cavitations due to the vapour sucked from the cargo tank.

Externally Mounted Pressure Transducers for Tank Level

Gauge and differential pressure transmitters are reliable, cost effective instruments to measure the hydrostatic level of liquids, such as water or fuel, in vented or sealed tanks. For a vented tank, the pressure transmitter should be mounted to the bottom.

Cargo tank Wärtsilä

Cargo tank. The liquid tight shell designed to contain the cargo. Deck tank A cylindrical gravity cargo tank, secured to transverse cradles on the cargo tank deck and used for specialised cargo. Gravity tank A cargo tank with design pressure not exceeding 0.7 bar gauge.Independent tank A tank entirely separated from the hull structure and not contributing to the strength of the

C Level Tank Level Gauge D&H Group

C Level Tank Level Gauge. C Level Tank level indictors are an innovative Level indicator designed for storage tanks. Just a simple mechanical float, a weight and a pulley system, with no gimmicks, no batteries. These gauges show the actual level of fluid in storage tanks, unlike other gauges

TANK BARGE CARGO TRANSFER PROCEDURES

A. The barge is a 200’X35’X12.5’ double hull, tank barge with 3 integral gravity cargo tanks. All transfer connection points are located near the bow. B. PIPING & VALVES: The cargo tanks are fitted with below deck fixed piping connected to the cargo pump.

Crude Oil Or Product Tanker Cargo Calculations Marine

Measurements should be taken in the units in which the tank capacity tables are presented. When taking custody transfer measurements, all cargo tanks, ballast tanks, bunker tanks, void spaces and cofferdams should be inspected and/or gauged as appropriate. Measurements should always be taken at the reference points noted in the capacity tables.

Tank Pressure Gauge Air Compressors Air Compressors

Shop our selection of Tank Pressure Gauge, Air Compressors in the Tools Department at The Home Depot.

Oil Pressure Gauge Install Censtar

Installing a digital oil pressure gauge on the hatch. Stickers http:// / Insta Boostedboiz Want to send us something? Boostedboiz

How to maintain tank pressure for a gas carrier carrying

Any heat input to the cargo will vaporize some of the liquid and gradually increase the tank pressure. Pressure vessels are designed to accommodate this increase, but on fully or semi refrigerated ships the boil off is condensed by the reliquefaction system and returned to the cargo tanks as a boiling liquid.

Regulations Section Federal Motor Carrier Safety

Question 1: Is the low pressure warning device required to activate before the tractor protection valve? Guidance: No. § does not explicitly require the warning device to operate before the protection valve. It is implied that if the operating pressure of the warning device is at least 1 / 2 of the governor cut out pressure, and that pressure is not less than the pressure at which the

Cargo handling and monitoring equipments for Liquefied Gas

The temperature indicating devices should be marked to show the lowest temperature for which the cargo tank has been approved by the administration. The vapour space of each cargo tank should be provided with a pressure gauge which should incorporate an indicator in the cargo control position. Fig:Liquefied natural gas ship on sea passage

Troubleshooting a bladder pressure tank

If it appears that a bladder tank is not operating correctly, check the tank’s air charge: Disconnect electrical power to the pump. Drain the tank by opening the closest faucet. Check the tank’s pressure by placing an air pressure gauge on the air charging valve on the top of the tank.

Guidelines for the Operation, Assembly, Repair, Testing

Guidelines for the Operation, Assembly, Repair, Testing and Inspection of Hazardous Material Cargo Tanks FINAL REPORT Submitted to: U.S Department of Transportation Federal Motor Carrier Safety Administration June 2009

Message

Message tel

tel Inquiry

Inquiry